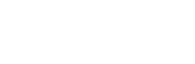

Quartz / granite sample tiles split machine

Classification:

Tag:

Technical parameters

Slide the table left and right to view all parameters

SY1T-101 For quartz small sample making, thickness can be adjusted to 0.5mm.

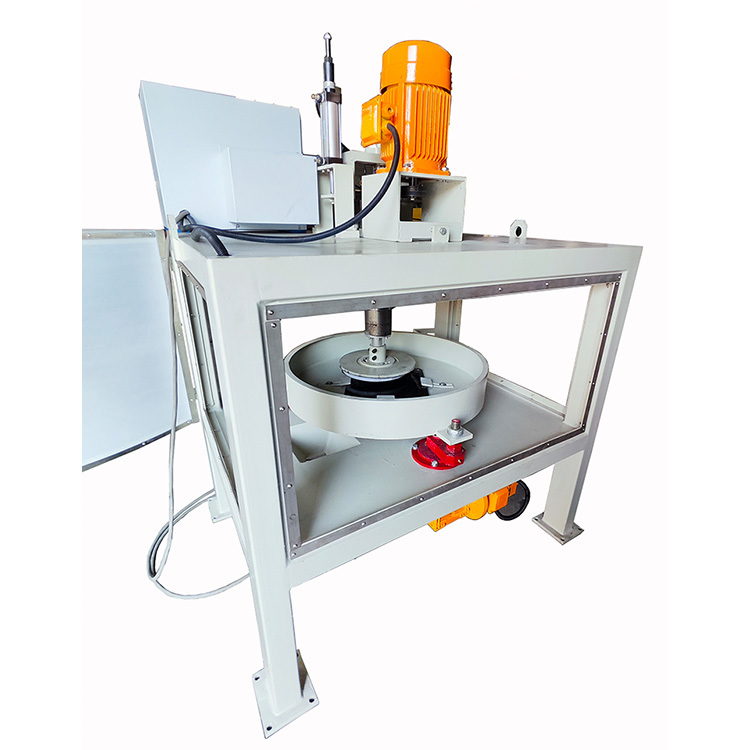

1. Total power: 15KW, 415V;

2. Working width: 70~120mm; Thickness: 12~30mm;

3. Working speed: 1m/min; Water consumption: 10 L/min;

4. The belt is driven by worm and worm wheel reducer;

5. Install one vertical cutting blades, the cutting thickness is adjusted the screws matched with the nuts manually, easy operation and control the precise thickness smoothly.

1. What are the machines configurations offering by Shuoyu?

Shuoyu is offering customized solution, Turn-key project, one stop services from raw materials to finished products. Popular options as following:

1) High level fully automatic systems linkages; Middle level systems, Manual low investment budget machines configurations;

2) Finished Slab size and thickness:

Super jumbo: 2000x3500mm;

Standard Jumbo: 1650x3250mm;

Small sizes: 1450x3050mm; 800x2500; 760x2440mm etc.

Thickness: a scope of 15mm to 50mm.

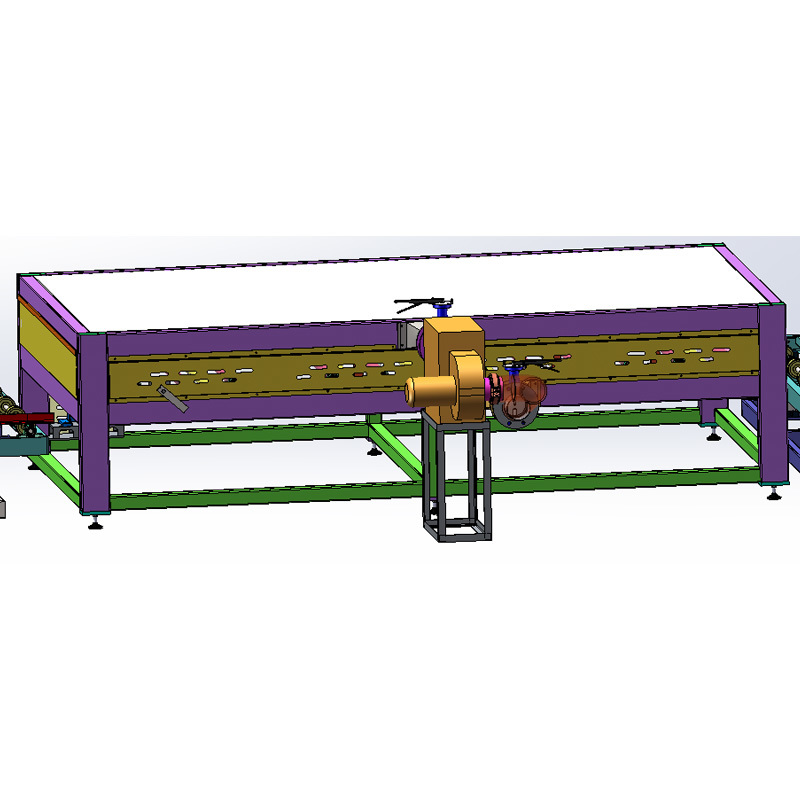

3) Standard combinations:

Two pressing lines matched with One polishing line.

3. What is the size of factory shed?

Two pressing lines matched with One polishing line.

Factory shed standard: Length 120~150meters in, width: 20~24 meters, height: Depends on production line raw material batching system(as actual need)

4. What about Shuoyu after-sales service?

We have rich experienced professional R&D team, following up from pre-sales on-sales, after-sales.

Our sales are online for 24-hours. We can also supply overseas install service.

Since year 2007, we have set up the quartz slab production base with 7 pressing lines and 3 polishing lines. Strong backup for the new investors on colors formula combinations.

5. What's your quality control system?

A: All our CNC machines are with CE certificate. Our QC department will do full test of each machine after finish, and send you test video and photos for confirm before delivery.

6. If I don't know how to use the machine, can you teach me?

A: Yes, sure. There is a U memory disc send together with the machine including machine install video, some video of how to use machine, user manual and software user manual . 100% educated users can know how to operate it. In case anything need help, please contact us at anytime.

7. Does the machine can be customized according to my requirements?

A: Sure, we have a strong technical team and have rich experience. OEM,ODM, OBM. The tenet of Shuoyu team: The customers' demand is at the priority.

8. Delivery time

According to different machines configurations, from 30~60days.

Q: Quality Warranty

12months under proper operations. Lifetime free services. Detailed will be mentioned in the Sales Contract (Invoice).

Our services:

A. Pre-sales service:

1.Indicate the specified function and equipment configuration.

2. Professional feedback on all kinds of technical questions.

3.Help to meet the needs of the individualized product.

For example, OEM,ODM, OBM.

4.Welcome to visit our factory at any time.

B. On-purchase service:

1.Provide the product performance and technical specification doc sheets.

2.Confirm the changes or special requirements in the production process.

3.Welcome to visit our factory for inspection.

C. After-sales service:

1.Provide installation, commissioning, operation, maintenance and other guidance.

2.Provide easy-wearing parts and common used spare parts.

3. 24 hours on line service.

4. Engineers available to service machinery overseas.

5. One year warranty, provide lifetime free technical upgrade support and maintenance services.

Product Consulting

Related Products